The basic materials for casting planter tuffas and leafmoldings are the same: Portland cement, fine play-sand (because it is clean of debris), and water. You’ll also need a garden or cement trowel and a couple of large plastic dishpan for mixing the cement, sand, and water. In one large dishpan, you’ll need to mix some water with the sand until it can be molded by hand as if building a sand castle on the beach. In the other dishpan, you will mix 1 part Portland cement with 2 parts sand. Add water until the mixture is the consistency of thick frosting.

The basic materials for casting planter tuffas and leafmoldings are the same: Portland cement, fine play-sand (because it is clean of debris), and water. You’ll also need a garden or cement trowel and a couple of large plastic dishpan for mixing the cement, sand, and water. In one large dishpan, you’ll need to mix some water with the sand until it can be molded by hand as if building a sand castle on the beach. In the other dishpan, you will mix 1 part Portland cement with 2 parts sand. Add water until the mixture is the consistency of thick frosting.

Portland cement comes in 40 lb. bags. They can be resealed after use. Play-sand comes in 40 lb. bags that are easily stored for future use.

For a casting planter tuffas, select a mold in the design of your finished product. It can be a simple bowl, tub, or other suitable casting object. It can be as large as you desire but remember that the larger the object, the heavy it will be. Some tuffas are 3 feet long and weigh more than 50 lbs.

Selecting a mold for a planter is merely a question of size and shape. Dollar stores have a wide variety of sizes and shapes. The exterior of the tuffas can be rough or smooth. The cement-sand mixture can be colored with a dry dye or left to a natural gray. It is also possible to finish them with paint or a stain.

Selecting a mold for a planter is merely a question of size and shape. Dollar stores have a wide variety of sizes and shapes. The exterior of the tuffas can be rough or smooth. The cement-sand mixture can be colored with a dry dye or left to a natural gray. It is also possible to finish them with paint or a stain.

Leaf-moldings are the most intricate of tuffas (cement moldings), but can be used in a wider variety of applications…tuffas make great year round outdoor planters.

For the leaf-molding tuffas, select a waxy texture that has a simple outline. Elephant Ear leaves make wonderful molds that can be used as birdbaths, plant holders, or just yard art in a flowerbed. The possibilities are limited only by ones imagination and the ease of construction and finish make these moldings ideal for the beginner as well as the advanced crafter and artisan.

Getting Started

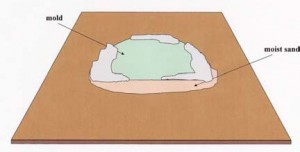

Mound up moist sand on a flat surface that is sufficient to fill the inside of the selected mold for the tuffas planter. This will provide support the select mold and prevent it from collapsing. Remove any excess sand from around the mold. You’ll want the table to be clean of sand before applying the cement-sand-water mixture.

Mound up moist sand on a flat surface that is sufficient to fill the inside of the selected mold for the tuffas planter. This will provide support the select mold and prevent it from collapsing. Remove any excess sand from around the mold. You’ll want the table to be clean of sand before applying the cement-sand-water mixture.

Apply a 1-inch thick cement-sand-water mixture to the outside of the mold. For extra strength on large objects, apply a mixture that is 1 to 2 inches thick. Cover the cement mixture on the mold with a wet cloth for at least 24 hours. Then remove the cloth and allow the cement mixture to dry for 4 days or more.

In finishing small planter-tuffas, provide drainage by drilling a small hole in the bottom of the tuffas mold. Cement drills are inexpensive and work well. Do not apply excessive pressure when drilling the holes or the tuffas may fracture. With large tuffas, several holes may be required.

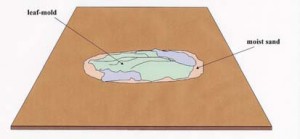

Leaf-moldings are handled much the same. Mound the moist sand to give the leaf a natural trough-effect. (Important: Place the leaf with the pronounced veins turned upward on the mound of moist sand. When the cement-sand-water mixture is applied over the leaf, the veins will provide a pronounced pattern in the cement. These veins can be accentuated when finishing the leaftuffas.)

Leaf-moldings are handled much the same. Mound the moist sand to give the leaf a natural trough-effect. (Important: Place the leaf with the pronounced veins turned upward on the mound of moist sand. When the cement-sand-water mixture is applied over the leaf, the veins will provide a pronounced pattern in the cement. These veins can be accentuated when finishing the leaftuffas.)

Apply about a 1-inch thick layer of the cement-sand-water mixture to cover the leaf. Use care to follow the shape of the leaf to give the finished molds the look of the actual leaf. Cover the leaf-mold with a moist cloth for about 24 hours and then let it air dry in the open for about 4 days. After 4 days, lift the dried cement leaf tuffas off the sand mound. The leaf will stick to the inside of the tuffas. The dry leaf remnants can be pealed away or scrubbed away with a brush.

The vein pattern will be embedded into the cement and there should be a small amount of cement bordering the outside of the leaf shape.

The vein pattern will be embedded into the cement and there should be a small amount of cement bordering the outside of the leaf shape.

The leaf tuffas can be decorated as desired. Green is always attractive while the veins can be painted a lighter green or cream to resemble a caladium. The paints are available at most craft stores. Apply a finishing coat of clear-coat polyurethane varnish to act as a weather sealant.

There are some safety practices that should be observed.

- Wear a dust-mask and eye protection when mixing the cement-sand-water mixture.

- Wear gloves when applying the mixture to the mold to prevent the hands from drying out.

- Work in a well-ventilated area due to dusty conditions that can be encountered.

If you have any questions, call or email Jan Bailey.